For road maintenance, Thermo-Lay asphalt patching machines stand out for being both reliable and...

Thermo-Lay's New Hook-Lift Asphalt Patcher Enhances Crew Flexibility.

A hook-lift truck offers today's fleet manager unmatched versatility. With a hook lift installed, a single truck chassis can be equipped with various attachments to perform a range of tasks—saving the capital cost and overhead of acquiring and maintaining several purpose-built trucks. For road crews, a hook-lift asphalt patching machine is the ideal solution when road repair is done on a part-time or seasonal basis.

A hook-lift truck offers today's fleet manager unmatched versatility. With a hook lift installed, a single truck chassis can be equipped with various attachments to perform a range of tasks—saving the capital cost and overhead of acquiring and maintaining several purpose-built trucks. For road crews, a hook-lift asphalt patching machine is the ideal solution when road repair is done on a part-time or seasonal basis.

- Reduce expense and wait times. By using an existing hook-lift truck, buyers can avoid the cost and delay of procuring a dedicated truck chassis. The Thermo-Lay unit's design can be adapted to any hook-lift style and A frame dimensions. Units are typically delivered in 60-90 days.

- Stay productive. When not repairing asphalt, owners can swap in other attachments like a dump body, flatbed, or tanker to get essential work done.

- Simplify ownership. A single hook-lift truck with multiple attachments requires just one:

- CDL driver

- Insurance policy

- Vehicle registration

- FET (federal excise tax levied on non-government entities)

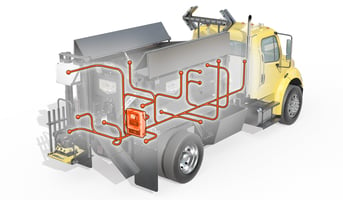

Thermo-Lay hook-lift machines are self-contained—an onboard hydraulic power unit means you never have to worry about truck compatibility. Models with 4.25 and 6.25 cubic yard capacities are available.

Like other Thermo-Lay asphalt repair machines (trucks, trailers, and slide-ins), the hook-lift unit sets a new performance standard:

- Dependable Material Feed: Multi-speed HD-steel auger with anti-bridge bar and auto-drawback prevent asphalt blockages and clogs.

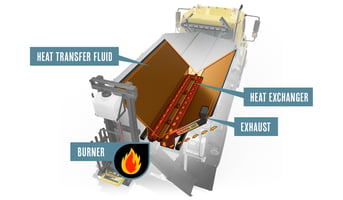

- Even Heating: Propane-fired radiant oil heating, plus electric overnight heat, ensures asphalt temperature remains consistent.

- Complete Discharge: Release agent spray bar prevents asphalt from sticking to hopper surfaces.

- Extra Safety: Operators are protected by multiple E-stops, safety interlocks, telescoping arrow board, and flashers.

- Total Versatility: For convenience and productivity, the tailgate grants access to tack gun, weed burner, cleaning wand, jackhammer, compactor, hand tools, and water connection.

For 48 years, American-made Thermo-Lay asphalt patching equipment has delivered unrivalled safety, capability, and ease of use. With more than 560 units shipped to customers across North America, Thermo-Lay has earned a reputation for reliability and low cost-of-ownership. All Thermo-Lay machines are custom-built at our Idaho headquarters by a team with decades of experience in road infrastructure maintenance and repair.

Want to experience the benefits of Thermo-Lay's hook-lift asphalt patch machine firsthand? Request a demo or sales consultation today:

Other options: Send an email or call (406) 259-9525.

Want to learn more about Thermo-Lay products, which include asphalt patch trucks (CDL and non-CDL), trailers, slide-ins, and hook lifts? Visit our website.

Want to keep up on the latest new about asphalt patching? Join Thermo-Lay's mailing list: