For road maintenance, Thermo-Lay asphalt patching machines stand out for being both reliable and...

5 Benefits of an Auto-Spray System for Your Asphalt Patch Truck

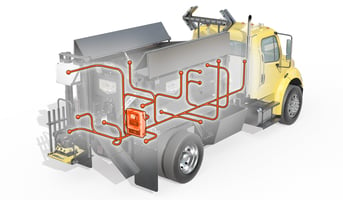

Asphalt repair crews know that reliable asphalt flow is key to staying productive when fixing potholes and patching utility cuts. Release agent is a substance applied inside the patching truck's hopper to prevent asphalt from sticking to the walls and obstructing flow. Typically, release agent is applied manually, but some newer machines offer a release agent auto-spray system to streamline application.

Asphalt repair crews know that reliable asphalt flow is key to staying productive when fixing potholes and patching utility cuts. Release agent is a substance applied inside the patching truck's hopper to prevent asphalt from sticking to the walls and obstructing flow. Typically, release agent is applied manually, but some newer machines offer a release agent auto-spray system to streamline application.

Should you specify auto-spray when purchasing your next asphalt patch truck? Consider these 5 benefits when making your decision:

- Prevent Slips and Falls. Any time a crew member climbs on the patching truck, there's the risk of injury from a fall. This risk is amplified when manually applying release agent using a hand sprayer. To fully coat the hopper walls, the crew member must maneuver to various locations around the hopper with only one free hand. With an auto-spray system, your crew can completely avoid climbing atop the truck.

- Minimize Traffic Exposure. Manual application of release agent is time consuming and laborious. For this reason, the release agent is often applied inconsistently, which can result in dry spots where asphalt sticks. When this happens, your crew must spend extra time in traffic working to dislodge clumps. An auto-spray system consistently applies release agent, helping prevent prolonged traffic exposure.

- Avoid Hopper Doors. The steel doors of the asphalt hopper are operated by remote hydraulics, which makes them essentially powerful jaws. When manually applying release agent or clearing clogs, your crew must work directly between these jaws. An auto-spray system keeps your crew away from the hopper doors and the rotating components within, removing a major opportunity for injury.

- Breathe Easy. Release agent is toxic. Applying release agent manually can put crews in contact with harmful aerosols and mists. With an auto-spray system, your crew can keep a safe distance during application. Auto-spray also allows the hopper doors to remain closed during application in order to contain harmful airborne substances.

- Conserve Release Agent. Release agent tank capacity on a truck is limited, and the cost of release agent continues to rise. With manual application, crews may overtreat areas of the hopper wall in an attempt to cover the full surface. With auto-spay, you get even application using the least amount of release agent--which means fewer trips to the garage for costly refills.

At Thermo-Lay, we design our machines with safety in mind. Our auto-spray system arose from a desire to minimize the risk of crew falling from the truck, getting hurt by the hopper's doors and rotating equipment, suffering a traffic injury, and breathing toxins. Beyond this, the auto-spray system helps minimize downtime and waste of release agent. If you share these concerns, a release agent auto-spray system may be an essential feature for your next asphalt patch truck.

Want to learn more about Thermo-Lay products, which include asphalt patch trucks (CDL and non-CDL), trailers, slide-ins, and hook lifts? Visit our website.

Want to experience the benefits of Thermo-Lay's release agent auto-spray system firsthand? Request a demo or sales consultation today:

Other options: Send an email or call (406) 259-9525.

Want to keep up on the latest new about asphalt patching? Join Thermo-Lay's mailing list: