A hook-lift truck offers today's fleet manager unmatched versatility. With a hook lift installed, a...

How Heat Transfer Fluid Helps Maintain Perfect Asphalt Temperature

If you drive a car with a gasoline or diesel engine, that engine is cooled by liquid, not air. If you take a polar plunge, expect hypothermia to set in 25 times faster than in air of the same temperature. At Thanksgiving, deep-frying an eight-pound turkey will take you half an hour, while baking it takes about three.

If you drive a car with a gasoline or diesel engine, that engine is cooled by liquid, not air. If you take a polar plunge, expect hypothermia to set in 25 times faster than in air of the same temperature. At Thanksgiving, deep-frying an eight-pound turkey will take you half an hour, while baking it takes about three.

What do these facts have in common? They all show that liquid can store and transfer heat much better than air.

At Thermo-Lay, our asphalt patch trucks take advantage of liquid’s superior heat transfer characteristics. Our heat transfer fluid (HTF) system maintains a consistent, uniform asphalt temperature under a wide range of working conditions. For crews in the field, this offers many benefits.

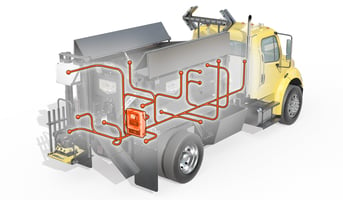

How it works. Each Thermo-Lay truck has a 350,000 BTU propane gas burner that fires into a welded steel heat exchanger. (See illustration.) That heat exchanger is submerged in a bath of HTF. This bath extends to fill the void between the inner and outer walls of the asphalt hopper and the trough around the auger, creating a “heat jacket” that evenly warms the asphalt payload.

Why it’s better. So how does HTF improve heating performance?

- Heat capacity. Liquid can store 4 times more heat by mass than air, which makes it less susceptible to external factors. Although outside temperature and airflow may fluctuate, the “thermal mass” of our heating system is able to maintain a consistent asphalt temperature.

- Heat circulation. Heat circulates naturally through liquid, and with substantially less dissipation than through air. This ensures that a consistent temperature is maintained across the surface of the hopper walls. As a result, the asphalt payload is heated uniformly across its mass.

How you benefit. Asphalt temperature that’s consistent and uniform sounds great, but how does it make the job of road maintenance easier?

- Productivity. When asphalt is heated uniformly, it’s less likely to stick to hopper walls and clog the dispensing system. With less clog-related downtime, crews can spend more time filling potholes. (For added performance, Thermo-Lay uses a metal dispensing auger that’s heated from the sides and below. Some other designs use a rubber conveyor belt with no heating beneath.)

- Safety. With fewer clogs, crews can avoid climbing the truck and entering the hopper to clear them. Less downtime in the field also means less traffic exposure.

- Quality. With asphalt dispensed at exactly the right temperature, it’s more spreadable and workable—which means you can do better work.

- Efficiency. Consistent, uniform heating extends the working life of the asphalt in the hopper. And because HTF is better able to retain heat, fuel economy is higher.

- Convenience. For overnight heating, an electric element heats the same HTF that the burner does, which allows a simple, seamless switchover. For both propane and electric heat, temperature setpoints are regulated precisely using a state-of-the-art CANbus closed-loop control system that constantly monitors temperature and controls burner/element output.

At Thermo-Lay, our advanced HTF system reflects 40-plus years of design evolution, with input from our many hundreds of customers. Want to see how it can keep you more productive, more efficient and safer out in the field? Request a demo or sales consultation today:

Other options: Send an email or call (406) 259-9525.

Want to learn more about Thermo-Lay products, which include asphalt patch trucks (CDL and non-CDL), trailers, slide-ins, and hook lifts? Visit our website.

Want to keep up on the latest new about asphalt patching? Join Thermo-Lay's mailing list: