A hook-lift truck offers today's fleet manager unmatched versatility. With a hook lift installed, a...

CANbus Controls: The Secret Power of a Thermo-Lay Asphalt Patcher.

For road maintenance, Thermo-Lay asphalt patching machines stand out for being both reliable and easy to operate, thanks to their use of CANbus controls integrated with the hydraulic system. This technology might sound complex, but it boils down to making the machine smarter, safer, and more user-friendly. Here’s a closer look at how CANbus improves the Thermo-Lay asphalt patching machine and what that means for those who use it.

Simplified Controls with a Single Touchscreen Interface

One standout feature of the Thermo-Lay machine is its touchscreen control panel, located at the tailgate. This touchscreen serves as the central hub for all machine functions, allowing operators to control everything from one easy-to-use interface. For truck-based models, there are also redundant controls in the cab. This dual setup ensures that whether you’re repairing roads or behind the wheel, you have full control over the machine's operations.

This single-point control system replaces a scattered array of buttons and switches, making it easier to manage the machine and reducing the chance for operator error. It simplifies the learning curve for new users and speeds up workflows so your crew can focus on the task at hand.

Reduced Wiring Complexity for Greater Reliability

CANbus technology significantly reduces the amount of wiring needed within a Thermo-Lay machine. Traditional electric controls often have a complex network of wires that can be prone to wear and tear, especially under the punishment of daily field work. By contrast, CANbus allows different components of the machine to communicate over common network cabling. This simplified approach not only makes the machine more reliable but also reduces the risk of electrical failures that can cause downtime.

With fewer wires to manage, there’s less chance of connections coming loose or getting damaged, leading to better overall performance and fewer maintenance issues. This means less time and money spent on repairs and more time getting the job done.

Self-Diagnostics and Troubleshooting

Another benefit of CANbus technology is its self-diagnostic capabilities. A Thermo-Lay machine can monitor its own performance in real time. If something goes wrong, it can provide detailed warning messages and diagnostic information. Should an issue come up, this feature helps operators quickly identify and address it without the need for extensive troubleshooting.

Instead of guessing what might be wrong or relying on trial and error, you can get clear, actionable information from the machine. This not only speeds up repairs, but also reduces the chances of minor issues escalating into bigger problems.

Improved Safety

Safety is a top concern when operating heavy machinery, and the Thermo-Lay machine takes this seriously with several key safety features. Multiple emergency-stop buttons are strategically placed on the machine to ensure that you can quickly shut down all functions in case of an emergency. This redundancy is crucial for preventing accidents and ensuring that the machine can be stopped immediately if needed.

Additionally, safety interlocks are implemented around moving parts such as the hopper doors, the auger, and the anti-bridge bar. These interlocks prevent these components from moving unless it’s safe to do so, providing an extra layer of protection for operators working near them.

Themo-Lay machines also include safety reminders to prevent unsafe actions. As an optional feature, the truck will warn a driver prior to travel if the compactor lift is not raised, the arrow board is not lowered, or the hopper doors are open. These reminders help ensure that the machine is in a safe state before the truck is moved, reducing the risk of accidents.

Closed-Loop Heating Control

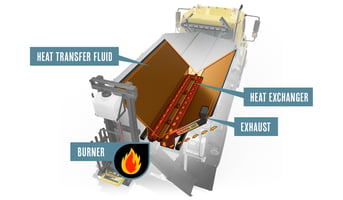

Maintaining the right temperature for asphalt is crucial for effective patching. The Thermo-Lay machine uses closed-loop controls for heating, which means it can precisely regulate the burner that heats the radiant oil system based on input from thermocouples. This system ensures that the asphalt remains at the optimal temperature for application (see image with readout of temperature setpoints), leading to better results and fewer issues with the asphalt congealing or cooling too quickly.

Maintaining the right temperature for asphalt is crucial for effective patching. The Thermo-Lay machine uses closed-loop controls for heating, which means it can precisely regulate the burner that heats the radiant oil system based on input from thermocouples. This system ensures that the asphalt remains at the optimal temperature for application (see image with readout of temperature setpoints), leading to better results and fewer issues with the asphalt congealing or cooling too quickly.

Automation of Key Functions

Automation is another area where CANbus technology shines. The Thermo-Lay machine automates functions to make operations smoother and more efficient. For instance, it features an auger-reverse function that automatically pulls any undispensed asphalt back into the hopper at the end of a job. This prevents the asphalt from hardening and clogging the auger, saving time on clean-up and maintenance.

Additionally, the machine can effortlessly switch from the gas burner to an overnight heater when the truck is connected to shore power. This feature ensures that the asphalt stays warm and ready to use without requiring manual intervention or risking heating issues.

Firmware Updates and Upgradable Features

At Thermo-Lay, our technology always continues to advance, and our machines are designed to keep up with these changes. The machine’s CANbus-controlled system allows for firmware updates, meaning that as new features and improvements become available, they can be integrated into the machine without needing major overhauls. This capability helps future-proof the machine and ensures that you can take advantage of the latest advancements in technology.

Easy Integration of Accessories

Finally, the Thermo-Lay machine is designed to make adding accessories straightforward. For example, the release agent spray bar, which helps prevent asphalt from sticking to the hopper walls, can be added easily thanks to the machine’s plug-and-play design. (The spray bar eliminates the need for operators to climb onto the truck and manually apply the release agent, making the process more efficient and safer.) In addition, an auxiliary CANbus-controlled hydraulic port makes it easy to attach other accessories, such as a jackhammer.

Conclusion

CANbus controls bring a host of benefits to a Thermo-Lay asphalt patching machine, making it a more reliable, safe, and efficient tool for road maintenance. From simplifying controls with a touchscreen interface to enhancing safety and automating key functions, this technology makes a real difference in the field. Whether you’re a seasoned operator or new to the job, these advancements help ensure that you can do your best work with maximum convenience and productivity.

Want to see how Thermo-Lay's CANbus controls can keep you productive, efficient and safe out in the field? Request a demo or sales consultation today:

Other options: Send an email or call (406) 259-9525.

Want to learn more about Thermo-Lay products, which include asphalt patch trucks (CDL and non-CDL), trailers, slide-ins, and hook lifts? Visit our website.

Want to keep up on the latest new about asphalt patching? Join Thermo-Lay's mailing list: